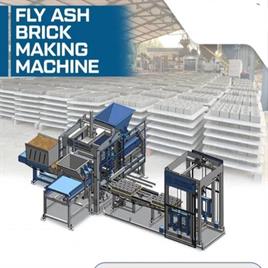

Automatic Hollow Block Machine, Capacity: 1000 Blocks/hr

Brand:

Others

Price ₹

25,00,000.00

₹25,00,000.00

| General Details: | |

| Model | Automatic Hollow Block Machine, Capacity: 1000 Blocks/hr |

| Automation Grade | Automatic |

| Others: | |

| Country of Origin | Made in India |

| Method | Hydraulic Pressure |

| Warranty | 1 Year |

Description

An Automatic Hollow Block Machine is an advanced industrial system designed to manufacture hollow concrete blocks with minimal manual intervention. These machines use a combination of hydraulic pressure, vibration compaction, and programmable logic controllers (PLC) to automate the entire block-making process—from raw material feeding and mixing to molding, compaction, and automatic ejection.Full Automation: All major operations—including batching, feeding, mixing, molding, vibration, compaction, and block ejection—are controlled automatically via PLC or computerized systems, ensuring high efficiency, consistency, and reduced labor requirements.Hydraulic & Vibration Technology: Employs powerful hydraulic systems (up to 25–40 MPa) and synchronized vibration mechanisms (up to 120 kN, 3800–4500 r/min) for dense, high-strength, and uniform hollow blocks.Production Capacity: Capable of producing thousands of hollow blocks per shift; for example, some models can output 8,000 hollow blocks in an 8-hour shift or over 2,000 blocks per hour, depending on machine size and configuration.Versatility: By changing molds, the machine can produce various concrete products—including hollow blocks, solid bricks, paving blocks, curbstones, and more—of different sizes and specifications.Material Flexibility: Can utilize a wide range of raw materials such as cement, sand, fly ash, slag, stone dust, and industrial waste, supporting sustainable building practices.Precision & Quality: Delivers blocks with tight dimensional tolerances, high compressive strength (typically 3.5–7.5 MPa), and low water absorption (<6%), meeting modern construction standards.Robust Construction: Built with heavy-duty steel frames and high-quality components for continuous, long-term industrial use.User Interface: Equipped with user-friendly control panels, LCD displays, remote control, and automatic fault diagnostics for easy operation and maintenance.

More Products from Robexo Industries

Robexo Industries Details

| GST | 24ABAFR0938H1ZE |

| Year of Establishment | 2015 |

| Nature of Business | Brick and Block Machine Manufacturer |

| Number of Employees | 1 - 50 |

| Turnover | 0 |

| Legal Status | Partnership |

if you are interested, please fill the below details: