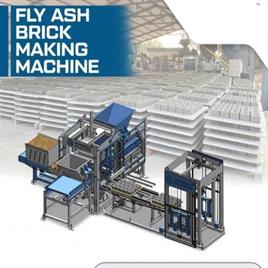

Paver Tiles Making Machine

Paver Tiles Making Machine, For Industrial

Brand:

Others

Price ₹

23,00,000.00

| General Details: | |

| model | Paver Tiles Making Machine, For Industrial |

| Capacity | 10000/8hr |

| Usage/Application | Industrial |

| Others: | |

| Brand/Make | Robexo |

| Country of Origin | Made in India |

if you are interested, please fill the below details: