Block Making Machine

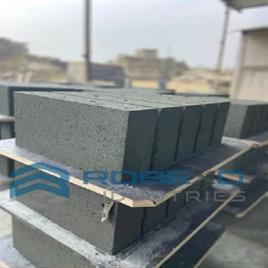

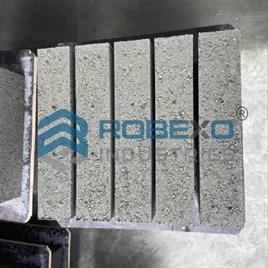

Solid Block Making Machine

Brand:

Others

Price ₹

24,50,000.00

| General Details: | |

| Model | Solid Block Making Machine |

| Material | Mild Steel |

| Block Type | Solid |

| Usage/Application | Block Making |

| Automation Grade | Fully Automatic |

| Capacity | 500-1000 Blocks per hour |

Automatic Solid Block Making Machine

Brand:

Others

Price ₹

22,00,000.00

| General Details: | |

| Model | Automatic Solid Block Making Machine |

| Material | Mild Steel |

| Block Type | Solid |

| Automation Grade | Fully Automatic |

| Others: | |

| Country of Origin | Made in India |

| I Deal In | New Only |

| Method | Hydraulic Pressure |

Vibration Block Making Machine

Brand:

Others

Price ₹

28,00,000.00

| General Details: | |

| Material | Mild Steel |

| Block Type | Solid |

| Usage/Application | Brick Making |

| Automation Grade | Fully Automatic |

| Capacity | 1000-1500 Blocks per hour |

| Others: | |

| Country of Origin | Made in India |

| Method | Hydraulic Pressure |

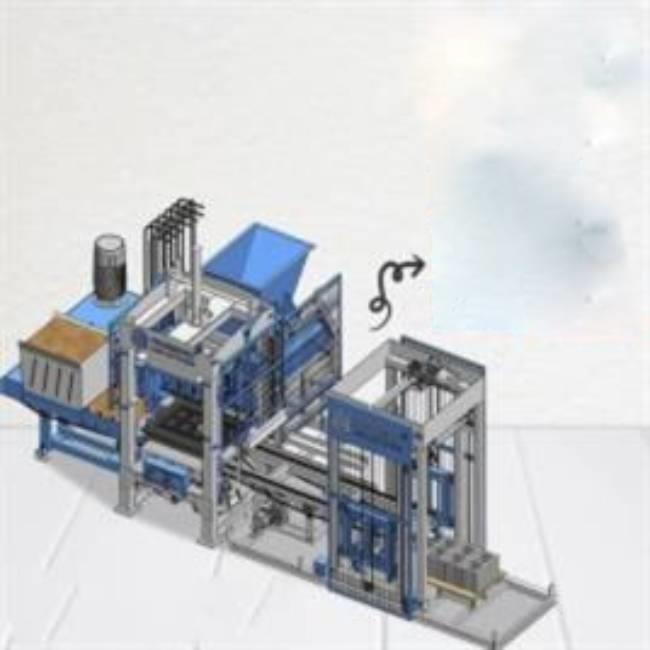

Automation Grade: Automatic RMC With Concrete Block Machine, Capacity: 1500 Blocks per Hour

Brand:

Others

Price ₹

65,00,000.00

| General Details: | |

| Automation Grade | Automatic |

| Capacity | 1500 Blocks per Hour |

| Others: | |

| Brand | Robexo |

| Country of Origin | Made in India |

| I Deal In | New Only |

| Minimum Order Quantity | 1 Piece |

Automatic Block Making Machine, Capacity: 1000 Blocks per Hour

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Model | Automatic Block Making Machine, Capacity: 1000 Blocks per Hour |

| Automation Grade | Automatic |

| Capacity | 1000 Blocks per Hour |

| Others: | |

| Country of Origin | Made in India |

| power | 50hp |

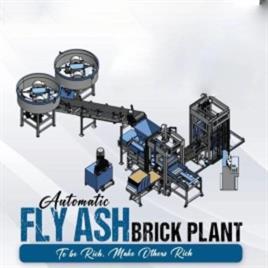

Automatic Solid Industrial Fly Ash Brick Making Plant, 1500 Per Hour, 1500 Bricks

Brand:

Others

Price ₹

31,00,000.00

| General Details: | |

| Model | Automatic Solid Industrial Fly Ash Brick Making Plant, 1500 Per Hour, 1500 Bricks |

| Automation Grade | Automatic |

| Capacity | 1500 Per Hour |

| Others: | |

| Brick Raw Material | Concrete |

| Brick Type | Solid |

| Capacity (Bricks Per Hour) | 1500 Bricks |

| Country of Origin | Made in India |

| Method | Hydraulic Pressure |

| Tolerance | 1 mm |

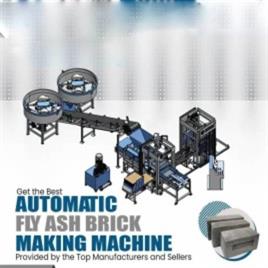

Solid Automatic Fly Ash Bricks Plant, 15000-17000 / Hour

Brand:

Others

Price ₹

29,00,000.00

| General Details: | |

| Model | Solid Automatic Fly Ash Bricks Plant, 15000-17000 / Hour |

| Usage/Application | Brick, Paver Block, Solid Block Making |

| Automation Grade | Automatic |

| Capacity | 15000-17000 / Hour |

| Others: | |

| Brand | Robexo |

| Brick Raw Material | Concrete |

| Brick Type | Solid |

| Capacity (Bricks Per Hour) | 1500 Bricks |

| Country of Origin | Made in India |

| Method | Hydraulic Pressure |

| Tolerance | 1 mm |

| Warranty | 1 Year |

Bricks & Blocks Fully Automatic Brick Plant

Brand:

Others

Price ₹

29,51,000.00

| General Details: | |

| Model | Bricks & Blocks Fully Automatic Brick Plant |

| Usage/Application | Brick, Paver Block, Solid Block Making |

| Automation Grade | Automatic |

| Capacity | 20000-23000 |

| Others: | |

| Brand | ROBEXO |

| Brick Raw Material | Concrete |

| Brick Type | BRICKS & BLOCKS |

| Country of Origin | Made in India |

| Tolerance | 1 mm |

Automatic Solid MS Fly Ash Brick Making Plant, 500 Bricks

Brand:

Others

Price ₹

29,00,000.00

| General Details: | |

| Model | Automatic Solid MS Fly Ash Brick Making Plant, 500 Bricks |

| Automation Grade | Automatic |

| Others: | |

| Brand | ROBEXO |

| Brick Raw Material | Concrete |

| Brick Type | Solid |

| Capacity (Bricks Per Hour) | 500 Bricks |

| Country of Origin | Made in India |

| Method | Autoclave Aerated |

| Tolerance | 1 mm |

Solid Automatic Fly Ash Brick Making Plant

Brand:

Others

Price ₹

28,00,000.00

| General Details: | |

| Model | Solid Automatic Fly Ash Brick Making Plant |

| Automation Grade | Automatic |

| Others: | |

| Brand | ROBEXO |

| Brick Raw Material | Concrete |

| Brick Type | Solid |

| Country of Origin | Made in India |

| Method | Hydraulic Pressure |

| Tolerance | 1 mm |

Solid Automatic Fly Ash Brick Plant , Capacity : 15000-17000

Brand:

Others

Price ₹

28,51,000.00

| General Details: | |

| Model | Solid Automatic Fly Ash Brick Plant , Capacity : 15000-17000 |

| Usage/Application | BRICK,PAVER BLOCK,SOLID BLOCK MAKING |

| Automation Grade | Automatic |

| Capacity | 15000-17000 |

| Others: | |

| Brand | ROBEXO |

| Brick Type | Solid |

| Country of Origin | Made in India |

| Tolerance | 1 mm |

Automatic Hydraulic Fly Ash Bricks Making Machine, Model Name/Number: RX08

Brand:

Others

Price ₹

65,00,000.00

| General Details: | |

| Model | Automatic Hydraulic Fly Ash Bricks Making Machine, Model Name/Number: RX08 |

| Material | Mild Steel |

| Block Type | Solid |

| Usage/Application | Brick Making |

| Automation Grade | Fully Automatic |

| Capacity | 1000-1500 Blocks per hour |

| Others: | |

| Brick Type | Solid |

| Country of Origin | Made in India |

| Hydraulic Tank | 180LTR |

| I Deal In | New Only |

| Method | Hydraulic Pressure |

| Minimum Order Quantity | 1 Set |

| Model Name/Number | RX08 |

| Provide After Sales Service | Yes |

| Raw Material | Stone Chips, Cement, Stone Dust |

| Tolerance | 1 mm |

| Warranty | 1 Year |

Automatic Solid Fly Ash Brick Plant

Brand:

Others

Price ₹

25,11,000.00

| General Details: | |

| Model | Automatic Solid Fly Ash Brick Plant |

| Automation Grade | Automatic |

| Others: | |

| Brand | ROBEXO |

| Brick Raw Material | Concrete |

| Brick Type | Solid |

| Country of Origin | Made in India |

| Method | Hydraulic Pressure |

| Tolerance | 1 mm |

Automatic Solid Auto Brick Making Machine, 1500 Bricks

Brand:

Others

Price ₹

27,50,000.00

| General Details: | |

| Model | Automatic Solid Auto Brick Making Machine, 1500 Bricks |

| Automation Grade | Automatic |

| Others: | |

| Warranty | 1 Year |

| Brick Raw Material | Concrete |

| Brick Type | Solid |

| Capacity (Bricks Per Hour) | 1500 Bricks |

| Country of Origin | Made in India |

| Method | Hydraulic Pressure |

| Provide After Sales Service | Yes |

| Tolerance | 1 mm |

Solid Fully Automatic Fly Ash Brick Making Plant

Brand:

Others

Price ₹

39,11,000.00

| General Details: | |

| Model | Solid Fully Automatic Fly Ash Brick Making Plant |

| Automation Grade | Automatic |

| Capacity | 25000 bricks per day |

| Others: | |

| Brand | ROBEXO |

| Brick Raw Material | Concrete |

| Brick Type | Solid |

| Country of Origin | Made in India |

| Method | Hydraulic Pressure |

| Tolerance | 1 mm |

Automation Grade: Fully Automatic Vibration Block Making Machine

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Model | Automation Grade: Fully Automatic Vibration Block Making Machine |

| Material | Mild Steel |

| Block Type | Solid |

| Usage/Application | Brick Making |

| Automation Grade | Fully Automatic |

| Capacity | 1000-1500 Blocks per hour |

| Others: | |

| Country of Origin | Made in India |

| Method | Hydraulic Pressure |

| Warranty | 1 Year |

Automatic Solid 8 CVT Brick Making Machine

Brand:

Others

Price ₹

24,51,000.00

| General Details: | |

| Model | Automatic Solid 8 CVT Brick Making Machine |

| Automation Grade | Automatic |

| Others: | |

| Brand | ROBEXO |

| Brick Raw Material | Concrete |

| Brick Type | Solid |

| Country of Origin | Made in India |

| Method | Hydraulic Pressure |

| Tolerance | 1 mm |

Automation Grade: Automatic Block Making Machine

Brand:

Others

Price ₹

30,00,000.00

| General Details: | |

| Model | Automation Grade: Automatic Block Making Machine |

| Block Type | Paver |

| Automation Grade | Automatic |

| Others: | |

| Capacity of Machine | 1000-1500 Blocks per hour |

| Country of Origin | Made in India |

Automation Grade: Fully Automatic Solid Block Making Machine, Capacity: 500-1000 Blocks per hour

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Model | Automation Grade: Fully Automatic Solid Block Making Machine, Capacity: 500-1000 Blocks per hour |

| Material | Mild Steel |

| Block Type | Solid |

| Usage/Application | Block Making |

| Automation Grade | Fully Automatic |

| Capacity | 500-1000 Blocks per hour |

| Others: | |

| Method | Hydro, Vibro |

| Warranty | 1 Year |

Automatic Block Making Machine, Capacity: 500-1000 Blocks per hour

Brand:

Others

Price ₹

3,00,000.00

| General Details: | |

| Model | Automatic Block Making Machine, Capacity: 500-1000 Blocks per hour |

| Material | Mild Steel |

| Block Type | Hollow |

| Usage/Application | Construction |

| Automation Grade | Fully Automatic |

| Capacity | 500-1000 Blocks per hour |

| Others: | |

| Brand | ROBEXO |

| Country of Origin | Made in India |

| Method | Hydraulic Pressure |

| Warranty | 1 Year |

Automation Grade: Fully Automatic Retaining Block Making Machine, Capacity: 500-1000 Blocks per hour

Brand:

Others

Price ₹

35,00,000.00

| General Details: | |

| Model | Automation Grade: Fully Automatic Retaining Block Making Machine, Capacity: 500-1000 Blocks per hour |

| Material | Mild Steel |

| Block Type | Solid |

| Usage/Application | Block Making |

| Automation Grade | Fully Automatic |

| Capacity | 500-1000 Blocks per hour |

| Others: | |

| Brand | Robexo |

| Conveyor Length | 22Ft |

| Cooling System | Yes |

| Country of Origin | Made in India |

| Method | Hydro+Vibro |

| Model Name/Number | Rx08 |

| Power | 30Kw |

| Vibrator Motor | 5+5HP |

| Warranty | 1 Year |

Automatic Fly Ash Brick And Paver Block Making Machine

Brand:

Others

Price ₹

24,51,000.00

| General Details: | |

| Model | Automatic Fly Ash Brick And Paver Block Making Machine |

| Material | Mild Steel |

| Automation Grade | Automatic |

| Capacity | 1500-2000 bricks per hour |

| Others: | |

| Brick Type | Paver |

| Method | Hydraulic Pressure |

| Model Name/Number | rx08 |

| System | PLC Controlled |

| Tolerance | 1 mm |

| Warranty | 1 Year |

Automation Grade: Automatic Block Making Machine, Capacity: 1000 Blocks per Hour

Brand:

Others

Price ₹

25,00,000.00

| General Details: | |

| Model | Automation Grade: Automatic Block Making Machine, Capacity: 1000 Blocks per Hour |

| Automation Grade | Automatic |

| Capacity | 1000 Blocks per Hour |

| Others: | |

| Country of Origin | Made in India |

| Electricity | 3 Phase |

| Minimum Order Quantity | 1 Piece |

Automation Grade: Automatic RE Block Making Machine, Capacity: 500-1000 Blocks per hour

Brand:

Others

Price ₹

35,00,000.00

| General Details: | |

| Model | Automation Grade: Automatic RE Block Making Machine, Capacity: 500-1000 Blocks per hour |

| Material | Mild Steel |

| Block Type | Solid |

| Usage/Application | Block Making |

| Automation Grade | Automatic |

| Capacity | 500-1000 Blocks per hour |

| Others: | |

| Brand | Robexo |

| Method | Hydro+Vibro |

| Model Name/Number | Rx10 |

| Power | 33kw |

| Warranty | 1 Year |

BRICKS & BLOCKS Automatic Brick Making Machines, 1500 Bricks, 20000-23000

Brand:

Others

Price ₹

32,00,000.00

| General Details: | |

| Model | BRICKS & BLOCKS Automatic Brick Making Machines, 1500 Bricks, 20000-23000 |

| Usage/Application | BRICK,PAVER BLOCK,SOLID BLOCK MAKING |

| Automation Grade | Automatic |

| Capacity | 20000-23000 |

| Others: | |

| Brand | ROBEXO |

| Brick Raw Material | Concrete |

| Brick Type | BRICKS & BLOCKS |

| Capacity (Bricks Per Hour) | 1500 Bricks |

| Country of Origin | Made in India |

| Tolerance | 1 mm |

if you are interested, please fill the below details: