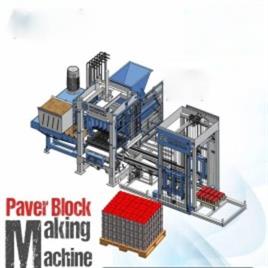

Automatic Paving Block Machine, Capacity: 1000 Blocks per Hour

Brand:

Others

Price ₹

20,00,000.00

₹20,00,000.00

| General details: | |

| Model | Automatic Paving Block Machine, Capacity: 1000 Blocks per Hour |

| Capacity | 1000 Blocks per Hour |

| Automation Grade | Automatic |

| Others: | |

| Country of Origin | Made in India |

| I Deal In | New Only |

| Technology | Hydro+Vibro Concrete Compacting Technology |

Description

An Automatic Paving Block Machine is a fully automated industrial machine designed to manufacture concrete paving blocks, interlocking pavers, curbstones, hollow blocks, and related products with high efficiency and minimal manual intervention. These machines combine advanced hydraulic pressing, vibration technology, and computerized controls to deliver consistent, high-volume output suitable for large-scale construction and landscaping projects.Automation: Operated via PLC or computerized control systems, automating material feeding, mixing, molding, compaction, and block ejection, which significantly reduces labor and increases productivity.Production Capacity: Capable of producing between 1,800 and 2,400+ paver blocks per hour, with some models manufacturing up to 24,000 concrete blocks or 800 m² of pavers in an 8-hour shift.Versatility: By changing molds, the machine can produce a variety of products, including double-layer (face mix) pavers, hollow blocks, curbstones, and even insulated bricks, with block heights typically ranging from 5 cm to 35 cm.Hydraulic & Vibration Technology: Utilizes high hydraulic pressure (up to 6000KN or 150–200 tons) and synchronized vibration systems to ensure dense, durable, and dimensionally accurate blocks.Heavy-Duty Construction: Built with robust steel frames and reinforced chassis for long operational life and reliability, even under intensive 24-hour operation.Efficient Material Handling: Features such as double hoppers for face mix production, forklift pallet transport systems, and modular vibration tables for easy maintenance and mold changes.Energy Efficiency: Power requirements typically range from 45 kW to over 137 kW depending on model and capacity, with energy-efficient motors and vibration systems.Labor Requirements: Despite high output, these machines require minimal personnel (typically 5–9 operators), further reducing operational costs.

More Products from Robexo Industries

Robexo Industries Details

| GST | 24ABAFR0938H1ZE |

| Year of Establishment | 2015 |

| Nature of Business | Brick and Block Machine Manufacturer |

| Number of Employees | 1 - 50 |

| Turnover | 0 |

| Legal Status | Partnership |

if you are interested, please fill the below details: