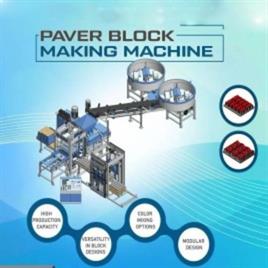

Automatic Zig Zag Paver Block Machine, Capacity: 1000 Blocks per Hour

Brand:

Others

Price ₹

25,00,000.00

₹25,00,000.00

| General details: | |

| Model | Automatic Zig Zag Paver Block Machine, Capacity: 1000 Blocks per Hour |

| Capacity | 1000 Blocks per Hour |

| Automation Grade | Automatic |

| Others: | |

| Country of Origin | Made in India |

| I Deal In | New Only |

| Minimum Order Quantity | 1 Set |

| Power Requirement | 45hp |

Description

An Automatic Zig Zag Paver Block Machine is a specialized industrial machine designed to produce zig zag-shaped concrete paver blocks through a fully automated process. These machines utilize hydraulic pressure and vibration compaction technologies to ensure high strength, durability, and uniformity in the paver blocks.

Automation: Operated via PLC or computerized controls, automating material feeding, molding, compaction, and block ejection, minimizing manual intervention and increasing production efficiency125.Production Capacity: Typically produces between 1,000 and 2,520 zig zag paver blocks per hour, depending on the model and configuration1245.Compaction Technology: Employs hydraulic and vibro-compaction systems (often referred to as HYDRO+VIBRO), combining high pressure (up to 70 tons) and vibration (60–90 Hz) for dense, durable blocks125.Block Quality: Delivers precise, dimensionally accurate paver blocks with tight tolerances (often within 1 mm), suitable for heavy-duty paving applications such as roads, walkways, and parking lots25.Material Handling: Designed for use with concrete mixes containing cement, stone chips, stone dust, and other aggregates25.Construction: Built with robust mild steel or heavy steel frames to withstand continuous industrial use.Versatility: Capable of producing various paver block shapes (zig zag, I-shaped, rectangular) by changing molds.Cycle Time: Each production cycle typically takes 15–30 seconds, enabling high throughput.These machines are widely used in the construction industry for the large-scale, efficient, and cost-effective production of zig zag paver blocks, supporting infrastructure and landscaping projects with reliable, high-quality paving solutions.More Products from Robexo Industries

Robexo Industries Details

| GST | 24ABAFR0938H1ZE |

| Year of Establishment | 2015 |

| Nature of Business | Brick and Block Machine Manufacturer |

| Number of Employees | 1 - 50 |

| Turnover | 0 |

| Legal Status | Partnership |

if you are interested, please fill the below details: