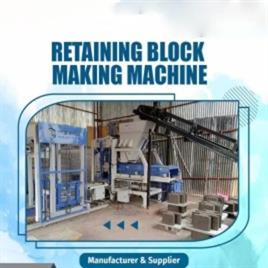

Automation Grade: Fully Automatic Retaining Block Making Machine, Capacity: 500-1000 Blocks per hour

Brand:

Others

Price ₹

35,00,000.00

₹35,00,000.00

| General Details: | |

| Model | Automation Grade: Fully Automatic Retaining Block Making Machine, Capacity: 500-1000 Blocks per hour |

| Material | Mild Steel |

| Block Type | Solid |

| Usage/Application | Block Making |

| Automation Grade | Fully Automatic |

| Capacity | 500-1000 Blocks per hour |

| Others: | |

| Brand | Robexo |

| Conveyor Length | 22Ft |

| Cooling System | Yes |

| Country of Origin | Made in India |

| Method | Hydro+Vibro |

| Model Name/Number | Rx08 |

| Power | 30Kw |

| Vibrator Motor | 5+5HP |

| Warranty | 1 Year |

Description

A Fully Automatic Retaining Block Making Machine is a sophisticated industrial system engineered to manufacture concrete retaining wall blocks with minimal manual intervention. These machines automate the entire production process—including raw material feeding, mixing, molding, high-pressure compaction, vibration, and automatic ejection—using advanced control systems such as PLCs for consistent, high-volume output.Automation: All stages, from material handling to block stacking, are controlled automatically, ensuring uniform quality and reducing labor requirements.Production Capacity: Capable of producing a wide range of block types and sizes (e.g., 400×200×200 mm retaining blocks), with typical outputs ranging from 1,350 to over 10,800 blocks per 8-hour shift, depending on block size and machine configuration.Compaction Technology: Utilizes high-frequency vibration (typically 3,800–4,500 r/min) and strong hydraulic pressure to create dense, durable blocks suitable for retaining walls and slope protection.Versatility: Can manufacture various retaining wall block designs (hexagonal, I-shaped, chain slope protection blocks, etc.) by changing molds, and may also produce hollow bricks, paving bricks, curbstones, and other concrete products.Material Flexibility: Processes a mix of sand, cement, industrial waste slag, and aggregates to produce eco-friendly, high-strength blocks.Control System: Operated via a PLC-based automation system for precise control, easy operation, and remote monitoring capabilities.Cycle Time: Fast molding cycles, typically 15–20 seconds per batch, enable high throughput.Construction: Built with robust steel frames and high-quality components for long service life and reliable operation in industrial environments.

More Products from Robexo Industries

Robexo Industries Details

| GST | 24ABAFR0938H1ZE |

| Year of Establishment | 2015 |

| Nature of Business | Brick and Block Machine Manufacturer |

| Number of Employees | 1 - 50 |

| Turnover | 0 |

| Legal Status | Partnership |

if you are interested, please fill the below details: