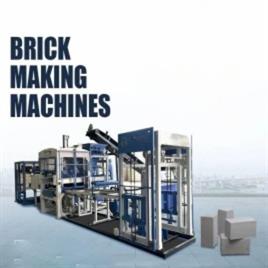

BRICKS & BLOCKS Automatic Brick Making Machines, 1500 Bricks, 20000-23000

Brand:

Others

Price ₹

32,00,000.00

₹32,00,000.00

| General Details: | |

| Model | BRICKS & BLOCKS Automatic Brick Making Machines, 1500 Bricks, 20000-23000 |

| Usage/Application | BRICK,PAVER BLOCK,SOLID BLOCK MAKING |

| Automation Grade | Automatic |

| Capacity | 20000-23000 |

| Others: | |

| Brand | ROBEXO |

| Brick Raw Material | Concrete |

| Brick Type | BRICKS & BLOCKS |

| Capacity (Bricks Per Hour) | 1500 Bricks |

| Country of Origin | Made in India |

| Tolerance | 1 mm |

Description

BRICKS & BLOCKS Automatic Brick Making Machines are advanced industrial systems designed to automate the production of various types of bricks and blocks, such as solid bricks, hollow blocks, paver blocks, and interlocking bricks. These machines use programmable logic controllers (PLC) or similar automated systems to manage the entire production process, including raw material feeding, mixing, molding, compression, and ejection, with minimal manual intervention.Automation: Fully or semi-automatic operation, allowing for high efficiency and consistent output.Versatility: Capable of producing a wide range of brick and block types and sizes by changing molds, including concrete, fly ash, and colored pavers.Production Capacity: High output, with some machines able to produce up to 20,000 bricks in an 8-hour shift or more, depending on the model and configuration.Technology: Employs hydraulic pressure and/or vibration systems to ensure dense, durable, and precisely shaped bricks and blocks.Material Flexibility: Can utilize various raw materials, such as cement, sand, fly ash, construction waste, and industrial byproducts, promoting sustainability.Ease of Use: Features user-friendly control panels, often with fault detection and self-locking for safe, reliable operation.These machines are essential in the modern construction industry for their ability to deliver high-quality, uniform bricks and blocks efficiently and cost-effectively, supporting large-scale building and infrastructure projects.

More Products from Robexo Industries

Robexo Industries Details

| GST | 24ABAFR0938H1ZE |

| Year of Establishment | 2015 |

| Nature of Business | Brick and Block Machine Manufacturer |

| Number of Employees | 1 - 50 |

| Turnover | 0 |

| Legal Status | Partnership |

if you are interested, please fill the below details: