Paver Tiles Making Machine, For Industrial

Brand:

Others

Price ₹

23,00,000.00

₹23,00,000.00

| General Details: | |

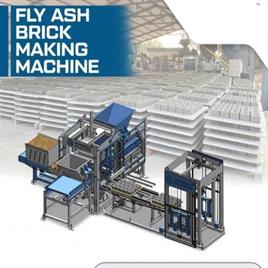

| model | Paver Tiles Making Machine, For Industrial |

| Capacity | 10000/8hr |

| Usage/Application | Industrial |

| Others: | |

| Brand/Make | Robexo |

| Country of Origin | Made in India |

Description

A Paver Tiles Making Machine, For Industrial use is a specialized industrial device engineered for the high-volume production of concrete or cement paver tiles and blocks. These machines are designed for continuous, efficient, and precise manufacturing processes, making them ideal for large-scale construction and landscaping projects.Industrial Application: Built for robust, continuous operation in industrial settings, capable of handling large production volumes efficiently.Material: Typically constructed from mild steel for durability and long service life.Production Capacity: Industrial models can produce between 2,000 and 7,000 tiles per shift or up to 18,000–19,000 tiles per day, depending on the machine and configuration.Automation: Available in manual, semi-automatic, and fully automatic variants, with automatic machines featuring PLC controls, automated batching, molding, and ejection for minimal manual intervention and maximum consistency.Compaction Technology: Utilizes hydraulic pressure and/or vibration to ensure dense, strong, and precisely shaped tiles with uniform surfaces.Versatility: Supports interchangeable molds to produce various tile shapes, sizes, and patterns, including interlocking, zigzag, and decorative designs.Material Handling: Equipped with hoppers, mixers, and conveyors for efficient raw material management and consistent quality.Quality Output: Delivers tiles and blocks with high compressive strength (often 40–50 MPa), low water absorption, and tight dimensional tolerances.

More Products from Robexo Industries

Robexo Industries Details

| GST | 24ABAFR0938H1ZE |

| Year of Establishment | 2015 |

| Nature of Business | Brick and Block Machine Manufacturer |

| Number of Employees | 1 - 50 |

| Turnover | 0 |

| Legal Status | Partnership |

if you are interested, please fill the below details: