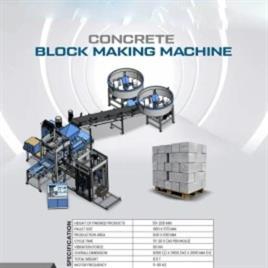

Solid Concrete Block Making Machine, Automatic

Brand:

Others

Price ₹

25,51,000.00

₹25,51,000.00

| General Details: | |

| Model | Solid Concrete Block Making Machine, Automatic |

| Capacity | 1000-1500 Blocks per hour |

| Method | Hydraulic Pressure |

| Others: | |

| Automation Grade | Automatic |

| Brick Type | Solid |

| Raw Material | Concrete |

| Warranty | 1 Year |

Description

A Solid Concrete Block Making Machine is an industrial device designed to manufacture solid concrete blocks of various sizes and shapes used in construction. These machines automate the mixing, molding, compaction, and curing processes to produce high-strength, uniform blocks efficiently.Block Type: Specializes in producing solid concrete blocks, which are dense and used for load-bearing walls, boundary walls, partition walls, and other construction applications.Raw Materials: Utilizes a mix of cement, sand, stone dust, stone chips, water, and sometimes fly ash or gravel as input materials.Molding Options: Equipped with interchangeable molds, allowing for the production of blocks in different sizes and dimensions (e.g., 400 x 200 x 200 mm, 300 x 200 x 100 mm, and custom sizes).Operation Modes: Available in manual, semi-automatic, and fully automatic models, with higher automation reducing labor dependency and increasing productivity.Production Capacity: Depending on the model, can produce from 500 up to 12,000 blocks per day or 500–1,000 blocks per hour.Compaction Method: Uses hydraulic pressure (typically 30–120 tons) and mechanical vibration to ensure each block is dense, strong, and dimensionally accurate.Durability: Built with robust materials like mild steel or stainless steel for long-lasting performance, even under heavy industrial use.Efficiency: Advanced machines feature quick-change molds, high-frequency vibrators, and PLC-based controls for precise operation and consistent output.

More Products from Robexo Industries

Robexo Industries Details

| GST | 24ABAFR0938H1ZE |

| Year of Establishment | 2015 |

| Nature of Business | Brick and Block Machine Manufacturer |

| Number of Employees | 1 - 50 |

| Turnover | 0 |

| Legal Status | Partnership |

if you are interested, please fill the below details: