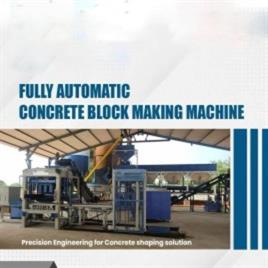

Solid Hydraulic Concrete brick Making Machine, 2500 Per Hour

Brand:

Others

Price ₹

65,00,000.00

₹65,00,000.00

| General Details: | |

| Model | Solid Hydraulic Concrete brick Making Machine, 2500 Per Hour |

| Brand | ROBEXO |

| Method | Hydraulic Pressure |

| Tolerance | 1 mm |

| Others: | |

| Automation Grade | Automatic |

| Brick Raw Material | Concrete |

| Brick Type | Solid |

| Capacity | 2500 Per Hour |

| Country of Origin | Made in India |

| power | 75HP |

| Provide After Sales Service | Yes |

| Warranty | 1 Year |

Description

A Solid Hydraulic Concrete Brick Making Machine is an industrial device designed to manufacture solid concrete bricks using hydraulic pressure as the primary compaction method. These machines are engineered for high efficiency, durability, and the consistent production of robust, dimensionally accurate bricks suitable for construction.Hydraulic Pressure: Utilizes powerful hydraulic systems—often with rated pressures of 16–21 MPa or more—to compress concrete mixtures into dense, high-strength solid bricks.Solid Brick Output: Specially designed to produce solid (non-hollow) concrete bricks, which are widely used for load-bearing and structural applications in construction.Automation Levels: Available in automatic, semi-automatic, and manual variants. Automatic models feature PLC-based controls for streamlined and high-volume production with minimal manual intervention.Production Capacity: Capable of producing thousands of solid bricks per hour. For example, some models can output 6,000–14,400 solid bricks per hour, depending on the machine and brick size.Consistent Quality: Ensures tight dimensional tolerances (often within 1 mm), high compressive strength (typically 3.5–7.5 MPa), and low water absorption (<6%), meeting modern construction standards.Versatility: By changing molds, the machine can produce various sizes of solid bricks and sometimes other block types.Durable Construction: Built with heavy-duty steel frames and components for long service life and reliable operation in demanding industrial environments.

More Products from Robexo Industries

Robexo Industries Details

| GST | 24ABAFR0938H1ZE |

| Year of Establishment | 2015 |

| Nature of Business | Brick and Block Machine Manufacturer |

| Number of Employees | 1 - 50 |

| Turnover | 0 |

| Legal Status | Partnership |

if you are interested, please fill the below details: